Write something

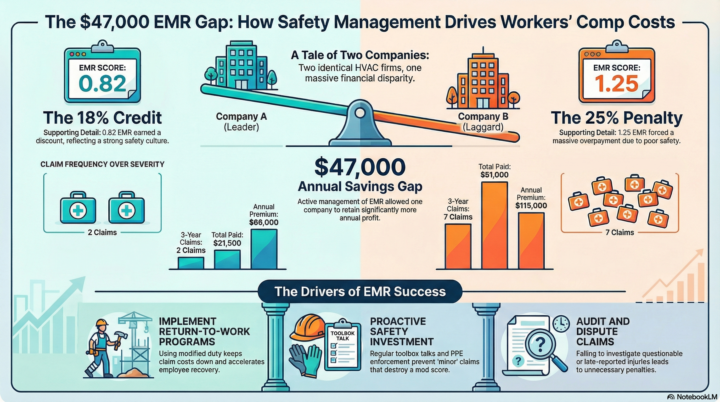

The $47,000 Difference: How Two Nearly Identical Companies Pay Wildly Different Workers' Comp Premiums

Let me tell you about two businesses I worked with in 2024. Both in HVAC installation. Both with about 17 to 20 employees and $3 million in annual revenue. Company A paid $68,000 in workers' comp premium. Company B paid $115,000 in workers' comp premium. Same industry. Same size. Same city. $47,000 difference. The reason? Experience Modification Rate (EMR). Company A: EMR 0.82 (Below Average Risk) This company had an EMR of 0.82—meaning they paid 18% less than the industry baseline for workers' comp. Their base premium was $83,000, but their mod brought it down to $68,000. Here's what they did right: 1. They managed claims frequency, not just severity. Over the past three years, they had two claims: - One $18,000 shoulder injury (employee slipped on a roof) - One $3,500 minor laceration (resolved quickly) Total claims: 2 - Total paid: $21,500 2. They invested in safety upfront. - Monthly toolbox talks on fall protection and ladder safety - Required PPE (hard hats, harnesses, gloves) on every job - Pre-job safety huddles before any elevated work - Incident reporting system (near-misses logged and reviewed) 3. They had a return-to-work program. When the shoulder injury happened, they immediately got the employee into modified duty. He couldn't climb ladders for 6 weeks, so they put him on equipment inventory, job site prep, and dispatch support. He never fully stopped working, which kept the claim cost down and sped up recovery. Result: EMR dropped from 0.95 to 0.82 over two years. Annual savings: $10,800/year. Company B: EMR 1.25 (Above Average Risk) This company had an EMR of 1.25—meaning they paid 25% more than the industry baseline. Their base premium was $92,000, but their mod pushed it to $115,000. Here's what went wrong: 1. They treated small claims like they didn't matter. Over the past three years, they had seven claims: - Three minor back strains ($4K, $6K, $5K) - Two hand injuries from power tools ($7K, $8K) - One knee injury from kneeling on concrete ($9K) - One slip-and-fall in a client's driveway ($12K)

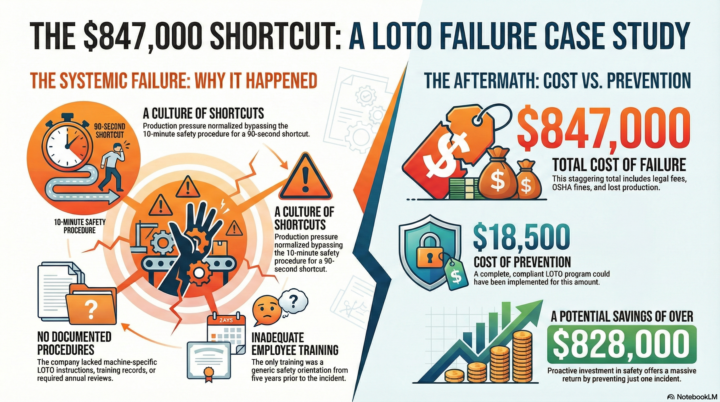

How a 15-Second Shortcut Ended up Costing $847,000

This is the story of a mid-sized packaging manufacturer in the Greater Houston area—$8M in annual revenue, 35 employees, solid safety record. They'd been in business 14 years without a serious OSHA violation. Until a Wednesday morning in March 2024 changed everything. 🔎The company ran a high-speed packaging line with an automated conveyor system. Around 10:30 AM, the conveyor jammed. Product was backing up. The production supervisor called over a maintenance technician, we'll call him Carlos, to clear the jam. This was routine—happened 2-3 times per week. Carlos knew the official procedure: shut down the line, lock out the main breaker panel, verify zero energy, clear the jam, restore energy, and restart. But the official procedure took 8-10 minutes. The shortcut version? Hit the emergency stop button, clear the jam, hit reset. 90 seconds max. The supervisor was under pressure to hit production targets. Carlos had cleared jams this way dozens of times. He hit the e-stop, opened the conveyor guard, and reached in to pull out the jammed cardboard. What Went Wrong: Another employee in the facility, unaware that Carlos was inside the conveyor, saw the line stopped and assumed it was a malfunction. He walked to the operator panel and pressed the reset button. The conveyor engaged instantly. Carlos's right hand was caught between the belt and drive roller. Three fingers were crushed. He was rushed to the ER. Two fingers were amputated. One was saved but permanently disabled. The OSHA Investigation 🔎: OSHA arrived within 48 hours. They requested: - Written LOTO procedures for the conveyor system (the company had none) - Training records for authorized LOTO employees (the company had a generic "safety orientation" from 2019) - Machine-specific energy control documentation (the company had never conducted an energy source audit) - Proof of annual LOTO procedure reviews (didn't exist) OSHA issued five separate citations: 1. Failure to develop machine-specific LOTO procedures – $18,700 penalty 2. Failure to train authorized employees – $15,400 penalty 3. Failure to conduct periodic LOTO inspections – $14,200 penalty 4. Inadequate energy control during servicing – $24,800 penalty (serious violation) 5. Failure to use lockout devices – $11,600 penalty

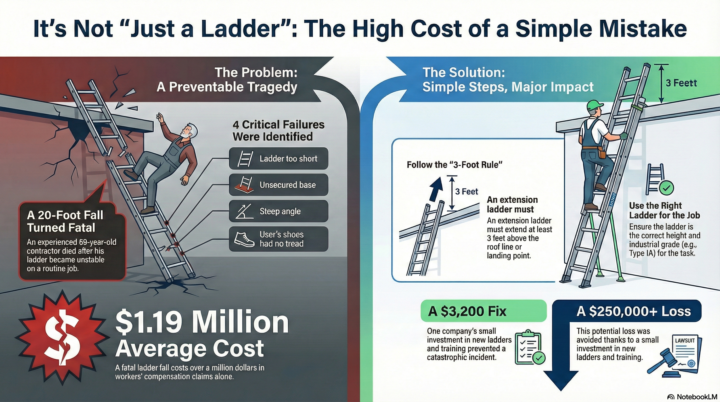

"It's Just a Ladder!" - Two Case Studies Part Two

Last year I was chatting with an industry friend and swapping stories about the weird and wild things we see in our world. He told me a the following story about a warehouse client he had written and a situation that happened to them a few years prior. An employee was using an 8-foot step ladder to access inventory on high shelving. The ladder wasn't tall enough, so the worker stood on the top cap platform—a clear OSHA violation. The ladder tipped. The employee grabbed the shelving unit to stop the fall, which then started to tip forward. A coworker saw it happening and stabilized the shelf before it collapsed. The employee walked away with a sprained wrist and bruised ribs. But the shelving unit held $80,000 in inventory. Had it collapsed, we'd be talking about: - One serious injury (likely fractures, possible head trauma) - $80K+ in damaged goods - OSHA citation and penalty ($16,550+) - Potential wrongful death if the shelf had landed on the worker The root cause? The company didn't have the right ladder for the job. They were using residential-grade Type II ladders (225 lb rating) when they needed industrial Type IA ladders (300 lb rating) that were tall enough to safely access the shelving. Luckily, they had a risk manager with experience to help them solve this problem. They replaced all their ladders, implemented a ladder inspection checklist, and required employees to verify ladder height before starting elevated work. 💵Cost of the fix: $3,200 in new ladders and training. 💰Cost they avoided: Easily $250,000+ in injury claims, fines, and inventory loss. Lessons for Your Business Lesson 1: "It's just a ladder" is the most dangerous sentence in workplace safety. Lesson 2: If your ladder doesn't extend 3 feet above the landing, don't use it. Get a taller ladder. Lesson 3: Worn-out, damaged, or wrong-type ladders kill people. Inspect before every use.

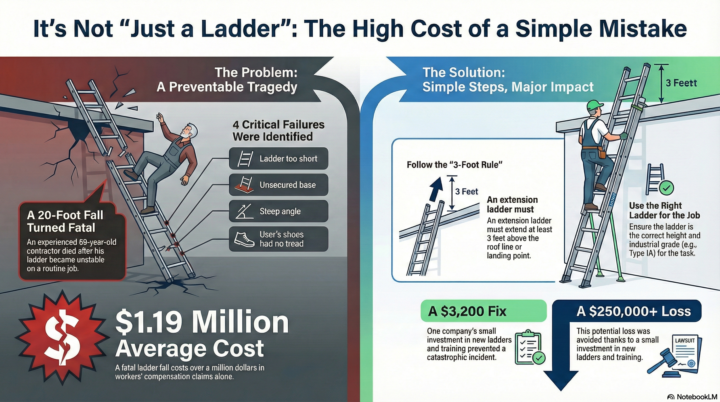

"It's Just a Ladder!" - Two Case Studies Part One

Today I decided to mix it up a little and give two examples of why being aware of OSHA Ladder standards isn't a choice. Case Study 1️⃣: On a Tuesday morning in July, a contractor, let's call him Mike, arrived at a residential job to clean exterior windows on a two-story house. He set up his 21-foot aluminum extension ladder and started working his way around the building. Sometime mid-morning, the ladder became unstable. Mike fell backwards from approximately 20 feet. He landed on concrete. Hard. A coworker found him face-up on the ground, still clutching the ladder rungs in both hands. Unfortunately, he died from his injuries that day. 🔎What the Investigation Found When investigators arrived, they discovered several critical failures: ❗The ladder wasn't long enough. To safely access the second-story windows, the ladder should have extended at least 3 feet above the roof line or landing point. This ladder didn't. This is OSHA's #1 cited ladder violation—1926.1053(b)(1). ❗The ladder wasn't secured. Extension ladders used for roof or elevated access must be tied off at the top and stabilized at the base to prevent displacement. This ladder was freestanding. ❗The ladder was set up at too steep an angle. Extension ladders should be positioned at a 4:1 ratio—for every 4 feet of height, the base should be 1 foot from the wall. Investigators determined this ladder was over-extended and placed at an unstable angle. ❗Mike's footwear had no tread. His work shoes were worn smooth, which likely contributed to losing footing on the ladder rungs. ❗There was no written hazard analysis. The company had no documented safety procedures for ladder work, no pre-job risk assessment, and no fall protection plan. The Hidden Risk: Working Alone Here's what made this tragedy even worse: The contractor was working alone. Had there been a second person on-site, they could have: - Stabilized the ladder from the bottom - Noticed the improper setup angle before anyone climbed - Called for help immediately when he fell instead of finding Mike lying undiscovered

1

0

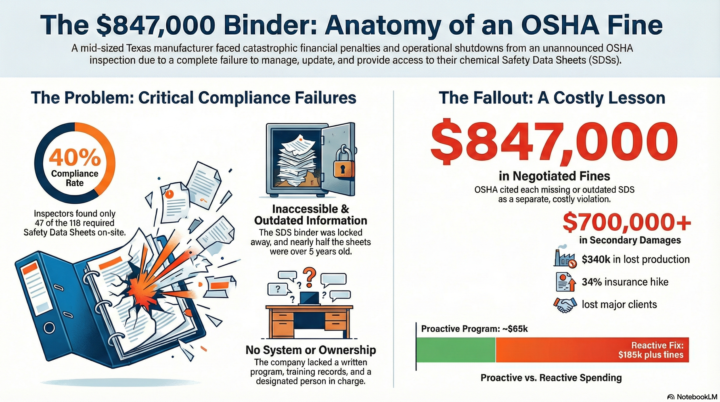

How Missing SDSs Cost a Manufacturer $847,000

This is a real story from a mid-sized Houston manufacturer. What happened to them is happening to businesses across the nation right now. OSHA showed up unannounced after an employee complaint about chemical exposure. The inspector asked three things: 1️⃣Written Hazard Communication program 2️⃣Safety Data Sheets (SDS) for all chemicals on-site 3️⃣Training records The plant manager walked the inspector to the maintenance office. A three-ring binder labeled "MSDS." Inside: 47 Safety Data Sheets. The facility used 118 different chemicals... That's a 40% compliance rate. 🔎What OSHA Found 1️⃣Missing SDSs: 71 chemicals had no SDS on file. When asked, the manager said, "The suppliers send them when we first order. We probably have them somewhere." OSHA doesn't accept "probably". Outdated records: Of the 47 SDSs, 23 were more than five years old. One was dated 2011. Chemical formulations change. Hazard classifications change. 2️⃣No version control: Multiple versions of the same SDS stored in different locations. Employees followed conflicting procedures. Inaccessible during shifts: The binder was locked in an office. Second and third shift employees couldn't access it without finding a supervisor with a key. 3️⃣No written program: No chemical inventory. No labeling procedures. No training records. Inadequate training: When the inspector interviewed production workers, they couldn't explain where to find the SDS for chemicals they used daily. No training documentation existed. So, what happened after all of this came to light? OSHA issued citations for each missing or outdated SDS as a separate violation. At $16,550 per violation, the initial package totaled $1,174,050. After negotiation and legal fees: $847,000. But that was just fines. OSHA halted operations in chemical areas for six days until SDSs were obtained and made accessible—$340,000 in lost production. Workers' compensation premiums increased 34% at renewal—$127,000 annually for three years. Two major clients—Fortune 500 manufacturers—audited the company after learning about violations. One put them on probationary status. The other moved business to a competitor.

1-6 of 6

powered by

skool.com/risk-management-tips-7690

Free community for business owners who want to simplify compliance, reduce risk exposure, and protect their profits. No BS. Pure strategy.

Suggested communities

Powered by