Activity

Mon

Wed

Fri

Sun

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

Jan

What is this?

Less

More

Memberships

Ai Bdarija

2.3k members • Free

AI Automation Circle

5.9k members • Free

AI Automation First Client

1k members • Free

AI Automation Society

237.5k members • Free

SW Automation

6.9k members • Free

Ai Automation Vault

15.2k members • Free

AI Automation Agency Hub

285.7k members • Free

3 contributions to AI Automation First Client

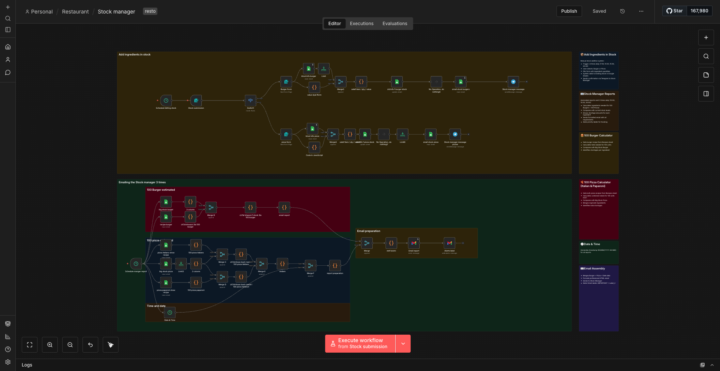

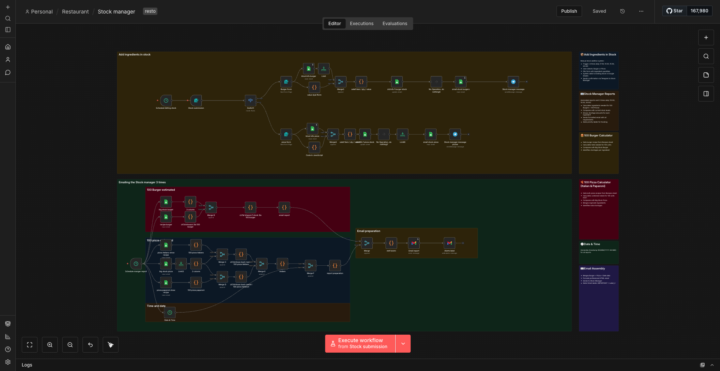

🚀 How We Automated Stock Management and Saved 12+ Hours Weekly

After analyzing our manual inventory system, we identified critical inefficiencies: stock updates took 45+ minutes daily and shortage alerts were reactive, not proactive. The Problem: 📦 Manual stock entry 4x daily 📊 No real-time shortage visibility 📧 Late supplier notifications 🔄 Disconnected recipe-to-stock calculations ❌ Frequent stockouts from poor forecasting Reality: Managing inventory for 200+ daily orders meant 3+ hours on spreadsheets plus costly last-minute supplier orders. The Solution: Built an intelligent n8n workflow automating inventory from entry to alerts: 1. Smart Stock Addition Scheduled forms (4x daily) Auto-updates to Google Sheets Instant Telegram confirmations 2. Predictive Shortage Analysis Recipe-based calculations (100 units) Real-time stock comparison Fuzzy matching for ingredients 3. Automated Reporting 3 daily reports (10:00, 15:00, 20:00) Formatted HTML emails Priority Gmail labels 4. Multi-Product Support Burger + Pizza tracking Separate recipe databases Merged shortage reports 💰 Impact: Time: 3+ hrs/day → 20 min = 12+ hrs saved weekly Cost: Labor: $576/month saved Emergency orders: $400+/month prevented Annual ROI: ~$11,700+ 🎯 Key Lessons: Predictive > reactive - Calculate needs before shortages hit Recipe integration - Connect formulas to inventory Scheduled automation - Regular checks prevent crises Smart matching - Fuzzy logic handles typos Tech: n8n, Google Sheets, Telegram, Gmail, JavaScript The Bottom Line: Simple automation transformed chaotic inventory into a predictive system that saves 600+ hours annually and cuts costs by ~$12,000/year. What processes are you automating in your business? I'd love to hear about different approaches and tech stacks people are using. Drop your experiences in the comments! 💬 hashtag#Automation hashtag#SmallBusiness hashtag#Productivity hashtag#Entrepreneurship hashtag#NoCode hashtag#n8n hashtag#BusinessGrowth hashtag#TechStack hashtag#StartupTips hashtag#DigitalTransformation

🍕 Restaurant Stock Management System - Looking for Feedback!

Hey! I've built an automated stock management workflow for a restaurant and would love your feedback and ideas for improvement. What It Does 📦 Stock Addition (4x Daily) - Scheduled trigger at 7:00, 10:30, 15:30, 20:30 - Staff selects product type (Burger/Pizza) via form - Adds quantities directly to Google Sheets stock - Sends Telegram confirmation to stock manager 📧 Automated Reports (3x Daily) - Runs at 10:00, 15:00, 20:00 - Calculates ingredients needed for 100 burgers + 100 pizzas - Compares requirements with current stock - Identifies shortages for each ingredient - Sends formatted HTML email with all details - Auto-labels emails as IMPORTANT in Gmail Current Features ✅ Real-time stock updates via forms ✅ Fuzzy matching for ingredient names (handles typos) ✅ Dual product support (Burgers & Pizzas) ✅ Recipe-based calculations from Google Sheets ✅ Automated shortage detection ✅ Professional email reports with timestamps Tech Stack - Trigger: Schedule + Form - Storage: Google Sheets (Big Stock, Recipes, Small Stock) - Notifications: Telegram + Gmail - Processing: JavaScript for calculations & fuzzy matching Questions - Has anyone built something similar? - Are there better ways to structure the Google Sheets data? - Any n8n nodes I'm missing that could simplify this? Drop your thoughts, suggestions, or questions below! All feedback welcome 🙏

5

0

🚀 NEW FREE COURSE: n8n Templates That Land Clients

Hey Community! 🔥 Just launched something massive... 📚 Introducing: n8n Templates That Land Clients The complete library of document automation templates I've been using to close clients consistently. What's Inside: ✅ 15+ Production-Ready Templates (I will post each day) - Invoice processing automation - Contract data extraction - Form parsing workflows - PDF to database pipelines - Automated report generation - And much more... You'll Master: 🎯 Adapting templates to ANY industry (legal, healthcare, accounting, real estate) 🎯 Customizing workflows without breaking them 🎯 Handling edge cases and weird document formats Why This Course? I got tired of seeing you all build from scratch when proven solutions already exist. Every template in this course has: - Been tested in production - Landed real clients - Generated recurring revenue The Reality: Stop spending weeks building custom workflows. Start with templates that already work. Customize for your client. Deploy in hours, not weeks. 💡 Quick Math: One template → One client → $500-1,500/month 15 templates → 15 opportunities → Do the math 😉 📍 Find It Here: Classroom → n8n Templates That Land Clients · AI Automation First Client. 🎁 What You Get: - Complete n8n JSON files (copy & paste ready) - Setup guides for each template - Industry customization instructions - Edge case handling strategies - My exact client pitch approaches Ready to stop building from scratch? Drop a "⚡" if you're diving in today!

1-3 of 3