Write something

How can I improve?

How can I improve this weld? I know it has a fish eye 😂 I'm trying to get rid of that! 123 amps 100Hz 64%EN 3/32 filler 3/32 tungsten #6cup 15cfh 1/8 aluminum

The right equipment makes a difference

My first half an hour messing around with stainless didn't go too well. Poor gas coverage was my guess. I was using the only cup that came with my torch, a 6. So I ordered the furick kit that was recommended and my first arc was already a decent improvement!

Tig welding mild steel

Hey yall, what is tig welded mild steel supposed to look like? I was welding this morning with a #12 cup, 25-30cfh, 1/2 stickout, and anywhere from 130 to 140 amps. All of them came out dull grey with very little color to it. Also, is tig welded mild steel supposed to be colorfull like stainless would be? Thanks

Understand and set your AC Balance ⚡️

Made a helpful short for setting your machine for welding aluminum!

WARNING ⚠️ Titanium/stainless steel

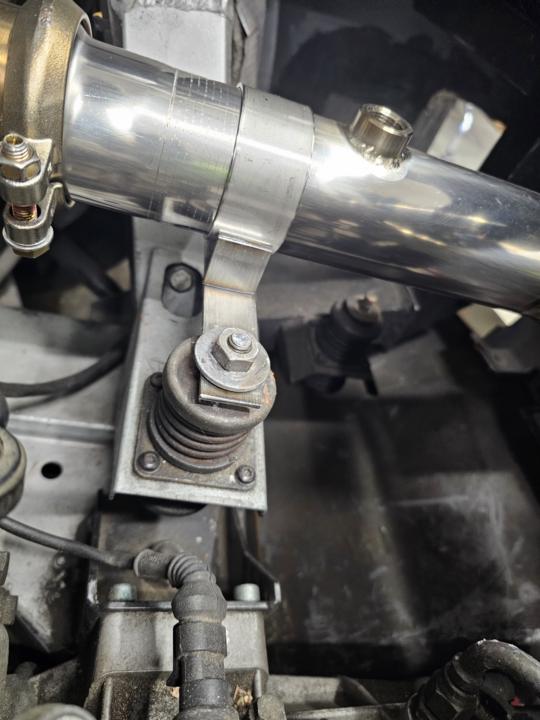

Here i have a stainless steel exhaust mount bracket that holds a titanium exhaust in place. I need to tac weld it. The problem is that if I tac the top part of the 1x1 inch metal flat bar to the stainless steel band, and I go to hot 🔥 the heat can transfer through the stainless steel and cause the stainless steel band to bond to the titanium tube which then will cause a hole. Stainless steel and titanium do not mix well when heated up to a point where they can be tac welded together. I give this warning that if you are in any situation where you need to tac or weld near the point of the two metals touching, be sure they dont bond or else they will have a GALVANIC CORROSION event where the titanium will become brittle and crumble. This happened to me a year ago go when I did this bracket and did the 1 inch bead, not thinking about how much heat transfers through the ss clamp. At the end I had to pry the clamp off and chunks of titanium came off with it that were on the inside of the clamp where the bead was laid. So, in this photo, I hit a super fast and cold tac doing everything I can to prevent heat transfer. The more ya know the better 😌

1-30 of 41

skool.com/motofab-performance-7936

1. Real time advice to level up your skills

2. Community of fabricators

3. Created by a Lockheed Martin welder for those serious about improvement

Powered by