Activity

Mon

Wed

Fri

Sun

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

What is this?

Less

More

Memberships

Welding/Fab SKOOL

248 members • Free

10 contributions to Welding/Fab SKOOL

Hey everyone 👋

My name’s Vincent, I’m 21 years old, and I’m currently in a two-year welding program. The program includes 8 months of internships in the industry, giving me the chance to gain real-world experience while learning in school. About halfway through the program, I discovered my love for TIG welding. Right from the start, it felt natural — I had a steady hand and quickly realized that this was the process I wanted to specialize in. That discovery shaped the rest of my journey. My first internship was at a large fabrication shop that built heavy mining equipment. I helped weld and fabricate massive mining buckets using flux core and multi-pass welds that were sometimes up to 5 inches wide. It was tough, rewarding work that gave me a solid foundation in structural welding. After that, I decided to steer my path toward TIG welding and joined a performance automotive shop. There, I worked mostly as a mechanic but also built custom exhaust systems for performance cars. It was the perfect place to practice and refine my TIG welding skills while doing something I’m passionate about. I’m now completing my latest internship at a shop that manufactures electrical service trucks. Each placement has helped me grow — whether it’s learning new techniques, understanding how different materials behave, or adapting to different industries. TIG welding is where I’ve found my passion, and I’m excited to keep developing my skills and building a career around it. I hope we can grow this community togheter by helping each other out in the best of our own abilities!

Hello my name is Keith

i am a journeyman tool and die maker of 40 plus years with some cnc knowledge. I am retiring soon and wish to have fun designing and building various projects.

Welcome New Members!

@Utyiuty Uyiyutituyi @Raymond Pereira @Martin King @Kees Boonsma @Steve Blane @Wolfgang Rittgers @Steven Smith @Rion Ward @Jonathan Hunt @Matthew Dow @Edgar Escobar @Clint Barta Thanks for joining, please make an introduction post and show us a project you’re working on or something you need help with!

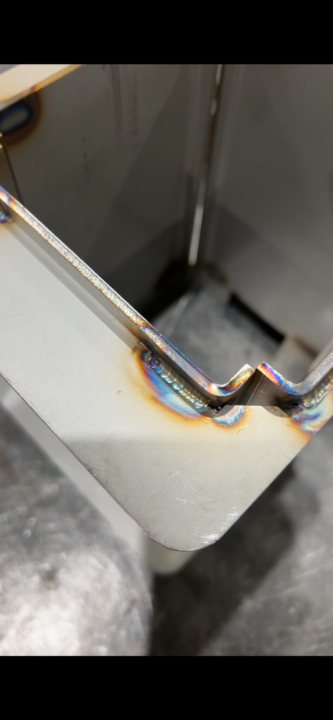

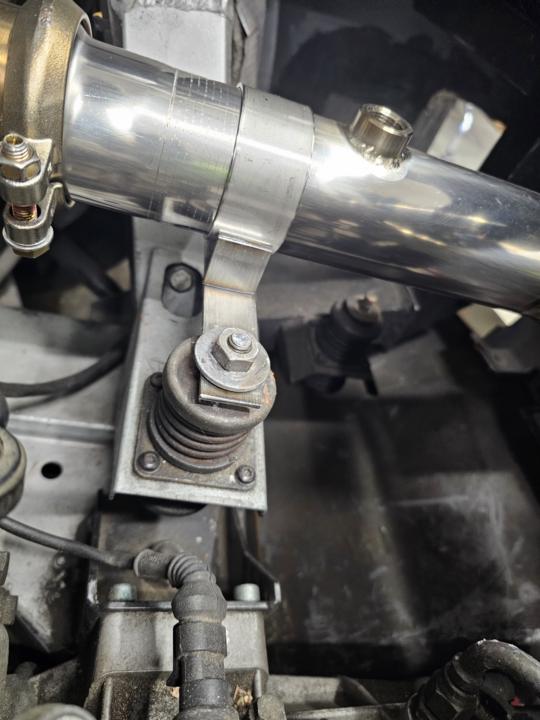

WARNING ⚠️ Titanium/stainless steel

Here i have a stainless steel exhaust mount bracket that holds a titanium exhaust in place. I need to tac weld it. The problem is that if I tac the top part of the 1x1 inch metal flat bar to the stainless steel band, and I go to hot 🔥 the heat can transfer through the stainless steel and cause the stainless steel band to bond to the titanium tube which then will cause a hole. Stainless steel and titanium do not mix well when heated up to a point where they can be tac welded together. I give this warning that if you are in any situation where you need to tac or weld near the point of the two metals touching, be sure they dont bond or else they will have a GALVANIC CORROSION event where the titanium will become brittle and crumble. This happened to me a year ago go when I did this bracket and did the 1 inch bead, not thinking about how much heat transfers through the ss clamp. At the end I had to pry the clamp off and chunks of titanium came off with it that were on the inside of the clamp where the bead was laid. So, in this photo, I hit a super fast and cold tac doing everything I can to prevent heat transfer. The more ya know the better 😌

1-10 of 10

Active 9d ago

Joined Aug 28, 2025

Powered by