Activity

Mon

Wed

Fri

Sun

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

Jan

Feb

What is this?

Less

More

Memberships

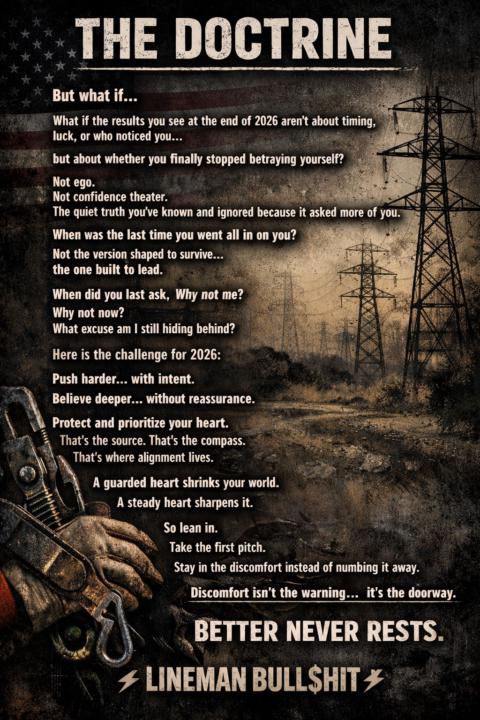

Lineman Bull$hit

393 members • Free

7 contributions to Lineman Bull$hit

Cradle to Cradle

A couple of months ago my company had a pretty bad accident in Wichita. Long story short, crew had broken cross arm, JM was unpinning the neutral in his leathers, cross arm broke and phase landed on his back. They have put a committee together made up of both management and BU guys to talk/implement cradle to cradle. We have never had it before. All I know is at face value you can't do anything without gloves and sleeves on. I'm sure this is not correct. My question is on my crew, our rule is whenever your going up with the intent to work primary or work in the MAD, or you can reach, extend, or fall into the primary MAD, you have your shit on. I'm sure some is up to how the company interprets it also. Just wanted to hear you alls thoughts/ what your companies do. Thanks

Module 1. My first hard lesson

I started in the EE98J program in October 2017...,(please allow me to explain myself... I'm just starting the lineman , pre aprentiship @ the local community college...I don't even have the "right" to even talk...and I hope to always have this reverence, but here am I and here it goes.) His name WAS Aiden McCullough. 22yo. Not even old enough to have lived. (It feels like ripping open an old wound talking about this...it hurts my heart.) What happened was, a semi truck flatbed trailer had 4 spools of 500KCmil weighing a couple of tons ea. Anyway, they unloaded the first one which had chocks. Every spool was required to have chocks, but only the first one did... The second one began to roll and the 1st year, inexperienced appreciate went to "stop" the spool. Milo Trujillo was the first one there...(God rest his soul, but that's another story.) He told me, "1st years have no sense"... I mumbled some BS and then he looked at me directly in the face, and said, "1st years have no sense." They said that anyone could go to the hospital and "visit" so I did, but when I got there, he was dead. The nurse asked if I wanted to say goodbye, but I declined. Now I'm going into something deeper, harder, scarier and I can't even explain to myself why. After reading some of these stories I realize there's no shame in quitting, but there's an "obligation" to stop work if something seems off. You have to know that a job, or a position isn't worth loosing a life. That's what I got.

3 likes • 28d

Read the last 2 sentences of what Roland Salas wrote. I've been in this trade 34 years and just about anything most people can imagine I've seen and that's why I refer to it as controlled chaos. That's why it's important to know your out "exit" at all times, because when shit goes sideways you damn sure don't want to be in its path. Although ive seen a bunch of shit go sideways no one ever suffered an injury other than a bruised ego

Module 1 — My First Hard Lesson

I was barely into my 2nd year of my apprenticeship and I was on distribution crew doing make ready work in Adel, Georgia. We had a new guy show up on Monday, the GF introduced him and everyone welcomed him and introduced themselves. All of the apprentices were stocking trucks and lineman were telling war stories about their weekend. We had a couple rear of poles that we had set the week prior, so we headed out to work those out. The new guy was with me and my journeyman and he wanted to see what this new guy was about because he was a white ticket. Well come to find out this guy knew something, he climbed better than a squirrel. He let my lineman take the lead and followed suit, he seemed as if he knew what he was doing and the day came and went safely. Fast forward a week and a half later, it's Thursday mid morning and we're working right down the side of the road, John the white ticket is in a bucket transferring phases from the old pole to the new one and my lineman Donnie is on the next pole doing the same. It's 3 phase cross arm construction with 3' spacing on neutral. I'm tending both trucks making sure both lineman have all they need to work with. They'd gotten all three phases tied in and John was taking the neutral up to the in. John hated the gloves & had commented on how hard they were on his body in the heat, he had removed his gloves because "its just the neutral" was his comment a few times prior to this set up. So he's got just leathers on with the neutral on the lip of the bucket without even a line hose on it, which i knew was wrong, but who am I to say something to a JL, so here he goes booming up and he gives the controls a little more than he should of and the Bucket lunges up and he puts the road phase primary right into the back of his neck. He takes 7200 volts into the back of his neck through his upper body and right to system neutral. I felt the heat from the ground, it was the first time I'd seen or heard a contact. I look up and there is smoke everywhere and the bucket is still there but I don't see John. At that time, i see the foreman is jumping in the belly of the bucket and goes to dead man and is lowering the bucket. A lady who lived across the road comes out her house screaming the fire department is on the way. The foreman gets the bucket broke over so we can get John out the bucket to start CPR and first aid, and that's the first and hopefully only fatality I'll ever see. John was almost unrecognizable, they said his core temperature reached several hundred over a thousand degrees in milliseconds, his body was basically a human pot roast. His flesh literally pulled off his body as we tried to pull him out of the bucket. It was at this point the foreman said "its too late, that's nothing we can do for him". And that's when it hit me that a man I just spoke with minutes ago was now dead. His wife no longer had a husband, his 2 little girls no longer had a daddy, that his parents no longer had a son. It would take a few days for me to realize the impact was far more widespreadthan just his immediate family. Had a apprentice working on the same job but another crew drop out of the apprenticeship because he didn't want that to happen to him. Flash forward about 2 weeks, the preliminary investigation comes back and it was determined that accident was 100% John's fault because he wasn't a lineman, he had done cable and telephone prior to that. His wife said about 2 weeks before he hired on, her got news of a third child and he said he had to find something better where he could give his family the life they deserved. So he went to the hall and got white ticket and get told he could work 6 months and if the guys he was working with would vouch for him they'd give him his yellow ticket. If that man would've humbled himself and told the hands he wasn't at the level they had him working at, they would've helped him out but instead he chose to work way out of his skill set and he paid for it with his life. The hard lesson i learned that day was never be to proud to say i don't understand or I don't know how to do that, and if you are something you say something. I had watched this guy for 7 days and watching him work compared to my lineman wasn't even comparable. He was making wrong moves that even i knew were wrong. I seen him handling the neutral without his rubber gloves on abd not putting line hose on it. If I had only spoke my concerns to my lineman, John might still be here to see his kids grow up and start lives of their own. I still picture the body after we got him to the ground and my foreman saying there's nothing we can do for him, and the smell of burnt hair, flesh and plastic permeating my nostrils. I made a promise to God and myself that day, that no matter what if I seen unsafe work being done or if something didn't feel right i would speak up about it, to get it corrected. If it wasn't corrected, I'd load my tools up, drag up and go somewhere else. I also promised myself I'd never let pride keep me from saying I didn't know something or was unsure exactly as to how something was supposed to be done. Thanks for letting me share, I pray for this story to possibly save a life one day, it may even be your own.

2 likes • Nov '25

Yes sir, you're spot on. Speed doesn't depend on how fast you get to the with but rather you do the work in the least amount of moves. I'm 56 and still out work most young guys, I do this by performing the least amount of steps and eliminating the back and toes. Stay safe & thanks for the reply

Module 1- My First Hard Lesson

It was August 23rd, 2020 at 9:45am. I'll never forget the date of that time. We had a three man crew and by 3 man I mean what it actually does not what companies think it means. Leadman, 2 Journeymen, 2 Hot Apprentices. We had been a crew for quite awhile, really had that good working relationship and trust between the 3 of us. We all knew each other's moves before we made them. We were "the crew". We had a pretty big hardening job. We could isolate a chuck of it but we were gonna do it hot because that's what this trade is. The day before we had sleeved out a set of switches and moved them a span for better access. Again, all hot with no issues. This day, we wanted the apprentices to come up with the plan. Tangent vertical pole with 3 phase break off also vertical on solid. 3 spans outside the sub. Had reclosing off (this circuit did not have hot line tag). Deenergized the break off (it was a tie for another circuit). We went to work. We were the crew that covered well and I mean cover for reach, extend, fall. The 6 foot bubble rule. We changed out the ridge iron and tied the neutral back in (shielded construction). Went down to our 1st phase. One bucket held the phase in the jib, the apprentices untied (journeyman in each bucket with one apprentice). Drove the phase out and the other bucket changed out the hardware and insulator. Drove the phase back in and tied it in. While the phase was being tied back in, the perform tie brushed the blanket that was covering the pole. I told them to not let the tie brush it, keep control. We were getting ready to move down to the next phase and we decided to go ahead and land our pole ground to the neutral. We were covering up well. My thought was you can't always cut the pole ground, we will teach them how to insulate for it. We went down to the next phase and did it the same way. As they were tieing the phase back in, the tie got away from the apprentice in my bucket. The blanket that was covering the pole was a little lower because they had drug the tie across it again. At the split second the apprentice in my bucket made contact with the pole ground, the apprentice in the other bucket started tieing in. I heard something, then the roar. At the split second the tie that got away from my apprentice and made contact with the pole ground, the other apprentice started tieing in. The roar was 795 burning down. The apprentice in the other bucket got the worst of it. He has flash burns on his face and hands. The apprentice in my bucket wasn't as bad though I will never forget her looking at me and I could visibly see her skin falling from around her face. Her face healed, his did not. Both weren't able to finish their apprenticeship and both lives were changed. Mine was to but differently. This was the moment where something changed in me. This all of a sudden became a different job. I had seen burn videos, watched and heard stories, but I had always in some way thought it would never happen on my watch. This job humbled me. From that day until I hang my tools up, I vowed to myself and the both of them, I would do anything and everything in my power to be a voice for change so "Not One More" will have to go through what they did. This is the incident that changed me and why I am that voice that doesn't give a shit who's feelings i hurt and not afraid to call anyone out on bullshit. This is why I am here and as involved as I am.

1-7 of 7

@timothy-leffew-3053

I'm a Journeyman Lineman & proud member of the IBEW for 34 years. I'm married with 3 children & 2 grandchildren. They are my reason for working safe

Active 28d ago

Joined Nov 30, 2025

ISFP

Sorrento, FL

Powered by