Activity

Mon

Wed

Fri

Sun

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

Jan

Feb

Mar

What is this?

Less

More

Owned by Patrick

A group for customers and community alike to see updates and progress on projects and discuss new projects or products.

Memberships

Inventors Academy

56 members • Free

Mechanical Engineering Mastery

288 members • Free

Lots Of Projects

163 members • Free

8 contributions to Eggers Engineering

Questions about Carbon

Can you give a brief overview of the process you use for making carbon fiber parts? My questions are mainly about the manufacturing process, but if you have design suggestions, I would love to hear those too. I will list some questions below in the comments

1 like • Oct '25

@Cameron Warech My vacuum system is a generic vacuum chamber and resin trap setup with a through-bag connector to apply pressure to parts evenly. A vacuum system is not necessarily necessary for hand-layup or pre-preg but it does allow for a superior reinforcement-matrix ratio for hand-layup and for debulking for pre-preg.

0 likes • Oct '25

@Cameron Warech some people use a heat sealer like in food processing to form their vacuum parts, however, most consumer applications will use a vacuum bagging tape (like a wax) applied to a Flange on moulds (design consideration) which the vacuum bag material is pressed onto. The previously mentioned through bag connector draws the vacuum, which is why vacuum sealing is so important

F1 style steering wheel for racing simulator

Fabricating an F1-style steering wheel for the racing simulator rig and chassis prototype. With years of experience in FDM 3D printing and expanding capabilities to include resin printing soon, if you have a part or project in mind to prototype or produce, get in touch to discuss how 3D printing can create your solution.

2

0

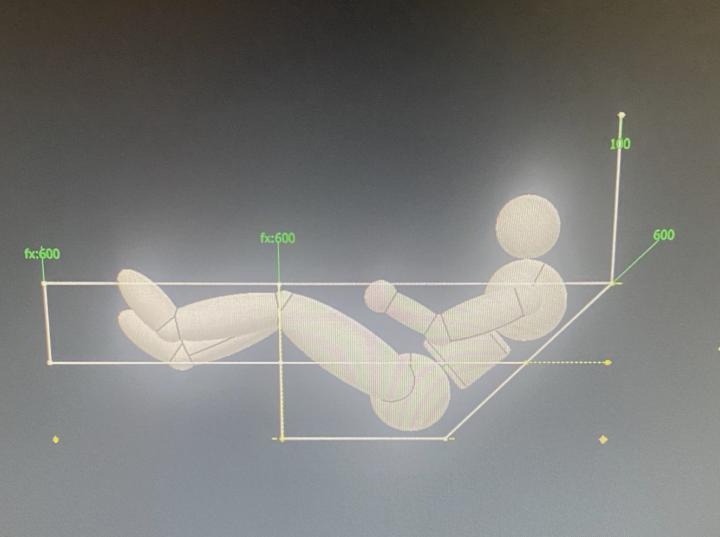

*Progress Update*

Been a busy few weeks for EggersEngineering: • The A1 prototype rear wing made its first appearance at the Teagle Excavations ARB Pines Enduro 400 • Lathe has finished restoration • Racing simulator has been dismantled and new design is being generated based on dummy shown in last post

2

0

*Prototyping and concept refining update*

A lot of work is going into 3D modeling for several upcoming projects, alongside physical prototyping on the 3D printer. The goal is to have a separate product—different from the one shown in the images—ready as a physical prototype for test fitting and display at the Pines Enduro.

2

0

Website and Product Launch Announcement

*Official date announcement!* Stay tuned for more teasers and updates leading up to the date.

2

0

1-8 of 8

@patrick-eggers-7471

I'm a University student from South Australia chasing my dreams

Active 1d ago

Joined Aug 21, 2025