Activity

Mon

Wed

Fri

Sun

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

What is this?

Less

More

Memberships

Solar Operations Excellence

170 members • Free

4 contributions to Solar Operations Excellence

Before buying more “AI”, what’s the one bottleneck you’d fix first?

Hello everyone, I'm digging into the friction of signal to action and learning how to turn alerts into real fixes on time for the solar energy operations. If you could fix one thing that would boost throughput for most operators, what would it be? Pick one (or add your own): A. Interoperability: alerts flow into work orders fast and clean. - Alert → Work Order sync ≤ 5 min - Device → asset mapping ≥ 98% - Fields don’t get lost (≤ 1% loss) - Status sync both ways Note: For mixed-vendor fleets, mapping is often <98% and alert→WO >15 min, which makes tickets explode from noise. What cutoffs do you use instead? B. Automate low-level office work - Auto-triage - Work orders pre-filled with context - Status + reports auto-updated - Admin time ≤ 12 min/WO C. Parts & first-time fix - Right parts picked ≥ 85% - First-time-fix ≥ 75% - Better routing + diagnostics D. Closeout & reporting - Proof on tickets ≥ 95% (photo/measure) - Report time: ops ≤ 24h, client ≤ 72h - Views matched to audience E. Something else: name it + one example I'll compile your feedback into a 1-page Readiness Checklist (with pass/fail cutoffs + “no-go” rules) and share it here. Many thanks in advance!

2 likes • Nov 1

D. Reporting Lack of consistency in reporting is a huge problem. Different techs have varying levels of proficiency with documentation. The best electrician may be terrible at explaining findings. If we can automate that, we can get a consistent data stream to make decisions from and eventually train an AI model on for predictive maintenance.

Official Launch

Dear early and founding members. Tomorrow is getting real as we open wide the gates. This community needs your help to bring in everyone willing and curious from your network. Share this LinkedIn live event to your network and we will get closer to the impact we need to make in our industry. https://www.linkedin.com/posts/calin-sas-m-sc-33984332_tomorrow-it-becomes-real-after-five-years-activity-7390112679866310657-8R2j?utm_source=share&utm_medium=member_android&rcm=ACoAAAbjGh0BtBElLSCIqlXNhFBWI95onkRMIB4

Does the Monitoring Match the Modeling?

Over the last couple of weeks, I’ve been diving deep into AlsoEnergy’s documentation and auditing the expected output of our systems against the PVSyst models we generated that proved they’re financially viable assets. My findings so far have shown significant inconsistencies in the way that sites have been set up (not Also’s fault; we’ve handled this internally) compared to the models, which has created no small source of frustration and confusion for our Asset Management, Engineering, and Financial departments. A quick breakdown: - The PVSyst model uses data from product manufacturers (solar modules, inverters, etc) along with historical weather data and shading maps to provide a reasonably accurate projection for how a system will perform. - AlsoEnergy sites get set up by adding in the same equipment, along with the weather sensors installed at site, and it creates estimates in real time based on weather data and equipment specs. - AlsoEnergy has several different options for modeling systems, each requiring different information to be accurate, or substituting various assumptions. Essentially, this seems like double work, attempting to recreate the same model that the system was built on, using a different platform, to act as the baseline from which the Weather-Adjusted estimates are generated. But there’s an important distinction: the PVSyst model is also a Weather Adjusted, but again, it uses historical weather data instead of momentary / current data. Where the Disconnect Happens: This is where many portfolios run into trouble. PVSyst is static—it captures design intent at a single point in time. AlsoEnergy (and other monitoring platforms) are dynamic—they reflect as-built reality and constantly changing site conditions. If the digital twin inside the monitoring platform doesn’t perfectly mirror the configuration and assumptions in PVSyst—things like stringing, inverter clipping limits, module binning, soiling losses, or albedo—it can lead to two parallel truths about performance that never fully align.

2 likes • Oct 29

@Sean Swentek for companies that build, own and operate assets using investor funds, any deviation from the ROI expectation eats into company profits and future projections. We expect the systems we build to operate the way they were designed, within a margin. When they don’t, we schedule the truck roll to correct the issue (which also eats margin). The practical problem (aside from finance) is determining whether the system is actually underperforming. If the models are misaligned, it’s chasing a ghost. Don’t get me started on when the modeling platform has issues ingesting the data 🙄

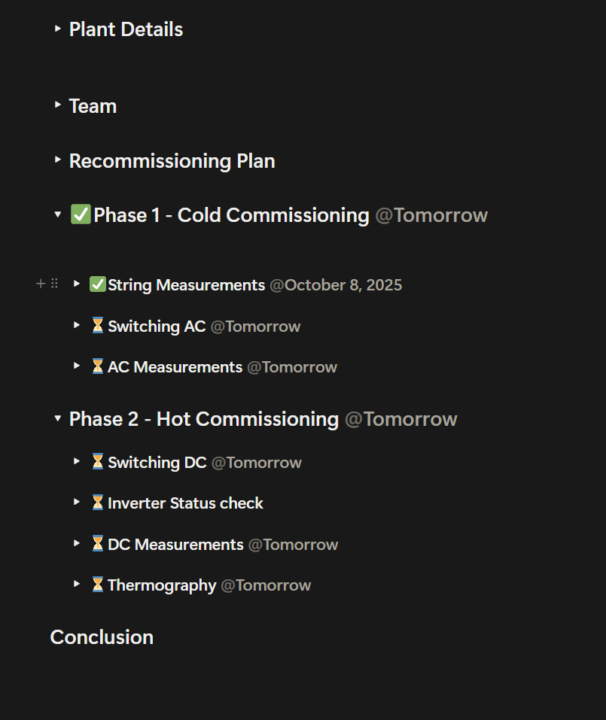

Commissioning Procedure

A small win after a few years of pushing this topic. Many issues in O&M and Asset management can be saved during commissioning. I cannot state more how much of a make or break moment it is. Yet it's reduced to flipping a switch and a high 5 if nothing breaks. Well, I did see things breaking. Could have been with fatalities. I embarked on a mission to make sure commissioning is done right. Super proud to share a win, that on of the contractors I work with implemented the best practice commissioning procedure. Added bonus, they used Notion for it. You cannot imagine how easy it was to verify, approve, and comment on the issues.

1-4 of 4

@joshua-hamsa-3548

NABCEP certified solar professional. Laser-focused on improving the solar industry.

Active 35d ago

Joined Oct 23, 2025

Powered by